The right bullet at the right seating depth can shoot like a house afire.

Pardon the personal question, but how deep is your seat?

This has nothing to do with furniture or your personal deep-seated convictions. It has everything to do with how accurately your rifles shoot. Bullet seating depth is critical.

You probably already know that a particular combination of primer, powder and bullet can significantly change accuracy in any rifle. Handloaders try all kinds of recipes to discover the ideal. But not all understand the critical role bullet seating depth plays in the process.

The distance from your bullet’s bearing surface to your barrel’s rifling usually contributes more to accuracy than do powder and primer combinations. The right bullet at the right depth can shoot like a house afire with a wide mix of powder charges. This is a big part of the reason handloads are usually more accurate than factory loads. Factory ammo must fit an industry standard overall cartridge length (OAL) so rounds will fit and function through all rifles and actions, so it’s rarely an ideal fit for any.

Of course, the barrel is key in all this. A bad barrel, usually one with wildly inconsistent internal dimensions or a damaged crown, can ruin the most carefully crafted handloads. Check the crown for damage and the rifling for deep pits or rounded edges on the lands.

Of course, the barrel is key in all this. A bad barrel, usually one with wildly inconsistent internal dimensions or a damaged crown, can ruin the most carefully crafted handloads. Check the crown for damage and the rifling for deep pits or rounded edges on the lands.

The breech should have a smooth leade, the transition from the smooth throat of the chamber to the rifling lands, which ramp up. Each ramp should be even and consistent with the others.

An eroded barrel can often be rechambered and set back to cut away the damaged rifling. A cheaper solution is to seat bullets farther out in the cases so they skip over any coarse, broken lands. The closer a bullet starts to the lands, generally, the less it wobbles before making contact. This minimizes disruption of the projectile and enhances accuracy.

If your barrel is in good shape, you can increase accuracy by tweaking the bullet seating depth. Most bullets shoot most accurately when seated to within .035 inch to .015 inch of touching the lands. Many benchrest shooters like them just kissing the lands. A few want even more contact, but that raises pressures, so you must start with light loads and work your way up, watching for pressure signs. Another hazard with touching the lands is that a bullet could get stuck and pull out when an unfired cartridge is removed from battery. This spills powder in the action and leaves a bullet in the bore, a dangerous situation.

DO NOT seat hunting bullets touching the lands. Back them off lands sufficiently (at least .015 inch) to be completely safe, yet close enough to get maximum accuracy.

Harder bullets like Barnes X, Nosler E-Tip and Hornady GMX without soft lead cores are usually more accurate when started .075 inch to .050 inch off the lands. Barnes recommends starting .050 inch off.

Harder bullets like Barnes X, Nosler E-Tip and Hornady GMX without soft lead cores are usually more accurate when started .075 inch to .050 inch off the lands. Barnes recommends starting .050 inch off.

Before stretching seating depth too far f, beware of exceeding magazine space. Many rifles are throated long enough to accommodate bullets seated quite long, but their magazines might be too short to fit them. Measure the inside of your rifle’s magazine first to determine its maximum overall cartridge length. You may seat deeper than this, but not longer. It’s recommended to seat so cartridge OAL is at least .030 inch under magazine length for smooth functioning. It’s rare, but possible, to seat bullets so long that a loaded round will not flip free of the ejection port. You’ll have to seat deeply enough to avoid this.

If the magazine and ejection port allow, fine-tune the seating depth to perfection. Always be sure to seat at least as deep as the caliber. A .308 bullet, for instance, should be seated at least .308-inch deep in the neck. Longer bullets will be easier to seat close to the lands than short ones. This is why persnickety shooters custom order barrels specifically for one bullet.

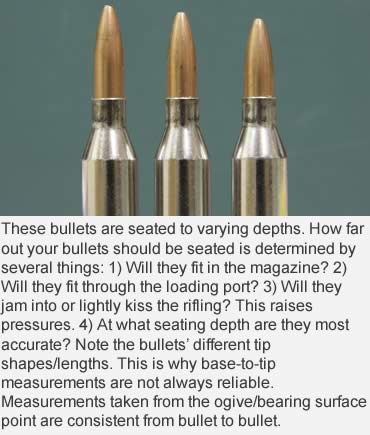

Now comes the hard part: determining maximum OAL. This number will be slightly different for every bullet due to nose shape or ogive. You need to measure from the front of the bearing surface, not the tip of the bullet, to the lands.

The old standard trick for this is to resize a case and start a bullet into it one caliber deep. No primer or powder should be in this dummy case! Then twirl the bullet above a candle so that soot builds up on it. Carefully insert this round into the chamber and close the breech/bolt. You may feel significant resistance. This is the bullet contacting the lands. Extract the round, seat the bullet slightly deeper and try again. Eventually you will reach the point where the cartridge/bullet chambers. Now fine tune this by again blackening the bullet and checking for land marks after you’ve chambered it. They will show as bright spots on the blacking. When you can just begin to see this contact, measure the OAL. This will be your starting point for seating deeper.

The old standard trick for this is to resize a case and start a bullet into it one caliber deep. No primer or powder should be in this dummy case! Then twirl the bullet above a candle so that soot builds up on it. Carefully insert this round into the chamber and close the breech/bolt. You may feel significant resistance. This is the bullet contacting the lands. Extract the round, seat the bullet slightly deeper and try again. Eventually you will reach the point where the cartridge/bullet chambers. Now fine tune this by again blackening the bullet and checking for land marks after you’ve chambered it. They will show as bright spots on the blacking. When you can just begin to see this contact, measure the OAL. This will be your starting point for seating deeper.

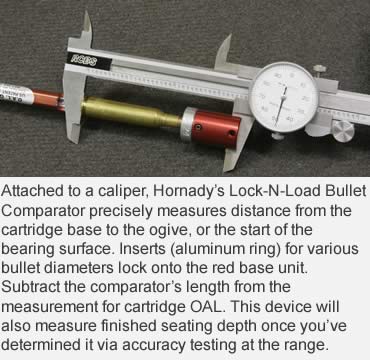

You have two options for measuring OAL: From the base to the bullet tip, and from the base to the ogive/bearing surface junction. Bullet tip length can vary as much as .050 inch, so it’s best to seat and measure at least 10 rounds to get an average. You can pull the bullets and reuse them. Alternatively, get a PTG Bullet Comparator, which looks like a bolt nut with multi-caliber holes around its perimeter. The span of the nut is constant, so you when you push a loaded cartridge into the appropriate caliber hole and measure from the cartridge base to top of the comparator, you need only subtract the width of the comparator to get an accurate measurement of OAL from the start of the bearing surface, not the bullet’s tip.

Another handy device for getting this bearing surface measurement is Hornady’s Lock-N-Load Overall Length Gauge. This tool uses a modified cartridge case screwed to a guide rod that pushes a case and loosely fitting bullet into the chamber. A plunger is then pushed up through the case to shove the bullet against the rifling. The plunger is locked into place, the unit is removed and measurements are taken from the start of the ogive to the cartridge base for a precise OAL.

Once you know the OAL, it’s a simple matter to turn down the seating die plunger bit by bit, measuring as you go until you get your desired seating depth/freebore. Some like to begin with .015” and work down, some vice versa. If you start this close, do so with a light charge of powder to prevent excessive pressures. You can always bring pressures/velocities up later if indicated.

The quickest way to determine which seating depth gives best accuracy is to build three sample loads at each depth — say .015”, .025”, .035” — and test each from the bench. The most accurate should suggest where you need to further tweak your settings, whether that be deeper or in between two of your tested depths. At some point you should hit the magic spot and see your groups shrink nicely, sometimes even amazingly.

Be aware that bullet lengths and shapes can change subtly from lot to lot, so if you seat too close to the lands with one bullet lot, a new lot could end up touching the lands and raising pressures. With hunting loads, you’re better off — and safer — settling for slightly reduced accuracy in exchange for a deeper seating depth that will accommodate dimensional changes among lots. You don’t need quarter-MOA accuracy to hit a deer at 500 yards, anyway. For more precise target and varmint loads, you should measure OAL for each new lot of bullets.

All this sounds more complicated and confusing than it really is. Once you’ve tried it, the veil lifts and the mystery is revealed.

Basically you are tailoring bullet seating depth for the “sweet spot” your individual rifle likes with a particular style/brand/weight bullet. Once you’ve measured your deep-seated accuracy challenges, you can fix them.

Read More Articles by Ron Spomer:

• Are Wildcats Worth It?: Your heart palpitates for a custom chambering, but think before you leap.

• 10 Steps to a Tack Driver: Turning a so-so shooter into a MOA rifle might be easier than you think.

This article was published in the July 2010 edition of Buckmasters GunHunter Magazine. Subscribe today to have GunHunter delivered to your home.