How to convert the world’s most popular rimfire rifle to .17 Mach 2

One of the greatest joys of shooting is personalizing a rifle — taking a gun off the rack and molding it to one’s specifications, needs and tastes.

There’s an abiding sense of accomplishment in customizing a firearm, even if you’re just making a few changes. In the case of the Ruger 10/22, customization can be just swapping a few parts to actually changing the caliber of the gun. The 10/22 in .22 Long Rifle can be converted to .17 Mach 2 (.17 HM2), and the 10/22 in .22 Win Mag can be turned into a .17 Hornady Magnum Rimfire.

The .17 Mach 2 conversion is by far the most common. Introduced in 2004, the .17 HM2 is based on a .22 Long Rifle CCI Stinger case necked down to .17 caliber. The Stinger case is slightly longer than a standard .22 rimfire and thus can be a problem for some .22 LR guns. But all the problems disappear when you neck down the case to .17 caliber. The .17 Mach 2 is close enough in size to the .22 LR that the standard 10/22 magazine will accommodate the smaller cartridge.

The .17 HM2 can be fired in any modern .22 rimfire rifle or pistol with a simple barrel change, unless it’s a semiautomatic. The semiauto’s bolt must move at the right speed and momentum to extract the empty case. One solution is to use a heavier bolt handle and stronger recoil spring, often sold as a kit. You can also install a heavier bolt, which slows the rearward thrust sufficiently to allow consistent cycling.

I’m told that the excessive force of the heavier bolt can, in extreme cases, cause the steel factory receiver pins to enlarge their holes in the aluminum receiver. To avoid this, I generally replace the factory pins with screw-in models developed by KIDD.

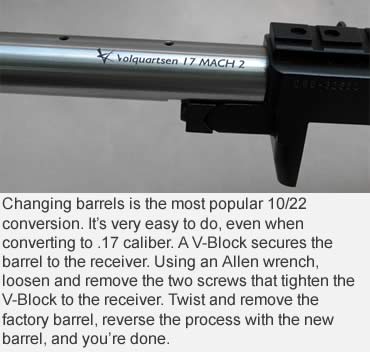

If you choose to go with a factory receiver and unthreaded barrel, you’ll probably want to replace the factory V-Block with a stronger Doug Koenig V-Block to enhance barrel-to-receiver lockup. I used a Koenig block to bolt an 18-inch Volquartsen stainless .17 HM2 barrel to a 10/22.

Going Inside

As noted in the last issue, drop-in components make customizing the 10/22 fairly easy even to folks with no gunsmithing skills.

It takes a tad more knowledge and expertise, however, to change things inside the receiver. If you want to smooth out the Ruger fire control system, quiet it or speed things up, there are some components available from Brownells, Volquartsen, KIDD, Power Custom, Clark Custom, Ranch Products and SKS Man that will help.

Brownells offers books, VHS tapes and DVDs that thoroughly explain and illustrate the disassembly and assembly of the Ruger 10/22 and its innermost workings.

While trigger weight is a personal choice, we all want a trigger with little creep (although you’ll always have creep in a semiauto), and little or no overtravel.

You can smooth out trigger pull and get rid of creep with a simple hammer and spring kit that features a precision-machined sear and polished surfaces. Some companies offer titanium hammers, triggers, bolt releases and/or extractors for faster lock time and cycling, which thrills target shooters. Springs, hammer and trigger shims are also available to tighten the package.

You can smooth out trigger pull and get rid of creep with a simple hammer and spring kit that features a precision-machined sear and polished surfaces. Some companies offer titanium hammers, triggers, bolt releases and/or extractors for faster lock time and cycling, which thrills target shooters. Springs, hammer and trigger shims are also available to tighten the package.

Be advised that the hammer is relatively easy to remove and replace for anyone with a decent background and understanding of the relatively simple 10/22 fire control system. But removing and replacing the trigger itself can be a bear. Best advice to the inexperienced is to leave it alone.

If, however, you do want to replace components with aftermarket items, dismantle the mechanism one piece at a time and replace that piece before going to the next component.

Do the work on a large sheet of paper, cloth or pad so that parts can be tracked. I’m not going to tell you how I know, but be advised that a tiny sear or trigger plunger spring, pivot pin or some other small but essential part falling off a bench onto a deep pile carpet results in a desperate and excruciating search.

You can also increase field accuracy by installing a trigger stop. As a shot is discharged, the trigger will move beyond the point where the hammer was released and the extra travel causes the gun to move a bit, throwing the shot. A simple trigger stop installed in the rear of the trigger guard can solve that.

Improving the Trigger

Improving the Trigger

The 10/22’s fire control system is held in its housing by four pins, which means that each serves multiple functions with regard to holding parts in place. Tap one out without full knowledge of its function, and you can trigger a spring-loaded mess that Rube Goldberg would be hard-pressed to reassemble. Again, trust me on this one.

If you are not well-versed in the complex trigger system, rest easy. Volquartsen, Clark, Jard, Hornet Products and KIDD have entire drop-in trigger systems set at various pull weights that replace the factory system. Simply tap out two receiver pins to remove the old system, and replace it with the custom job.

Most come with pre-set trigger weights or ranges, adjusted for creep and overtravel, and simply slide in to replace the factory system. All include an extended magazine-release lever. Some of the complete systems, such as Hornet Products’, are in the same price range as the components kits, while others range upwards of $300.

If you’re converting a 10/22 to a .17, however, most manufacturers will advise against using an extremely low trigger weight. The trauma of the rebounding heavy bolt may inadvertently trigger another round if the trigger weight is below 2 1/2 pounds.

In my experience, there are no clunkers among the drop-in systems; any will make the 10/22 more user friendly and substantially improve its performance. I opted for a KIDD drop-in unit for the .17 HM2 conversion and a Boyd’s Dakota Will laminated stock.

The tightness of the action screw will have an effect on 10/22 accuracy, and I generally replace the slotted factory model with a Volquartsen Allen-head screw for better “tuning” of the tightness.

Bedding the barrel can virtually eliminate the accuracy variables concerned with the receiver screw. Bedding was unnecessary in the .17 HM2 conversion, however, since the Boyd’s stock is milled for good support around the action screw and a support pad cut into the tip of the fore-end.

With a little tweaking, and topped with a BSA Sweet 17 ranging scope, my converted .17 HM2 became your basic long-range squirrel gun.

This article was published in the October 2008 edition of Buckmasters GunHunter Magazine. Subscribe today to have GunHunter delivered to your home.